Your Cart is Empty

In metallurgy, heat treatment refers to the use of heat to alter the properties -- strength, ductility, hardness, rust-resistance, etc. -- of metal. It's been fundamental in producing some of the world's highest quality swords, including the traditional Japanese katana. There are several different processes used in heat treatment, however, some of which we're going to explore.

In metallurgy, heat treatment refers to the use of heat to alter the properties -- strength, ductility, hardness, rust-resistance, etc. -- of metal. It's been fundamental in producing some of the world's highest quality swords, including the traditional Japanese katana. There are several different processes used in heat treatment, however, some of which we're going to explore.

Annealing

Annealing specifically involves heating a metal to temperatures that exceed its "recrystallization" temperature and then cooling the metal. By doing so, atoms within the metal migrate to form crystal-like structures, which typically increases its ductility and strength. For copper, steel and silver, annealing is performed by heating the metal until it's glowing, after which it's allowed to cool until room temperature.

Precipitation Strengthening

Also known as age hardening and particle hardening, precipitation strengthening is a heat treatment process that's performed to improve the strength of metal. It produced dispersed second-phase particles (known as precipitates) within the metal to prevent dislocation.

Some of the most common metals in which precipitation strengthening is used include aluminum, nickel, magnesium, titanium, steel, stainless steel, and other structured alloys.

Quenching

Of course, quenching refers to dousing heated metal with oil, water or other liquids for the purpose of rapidly cooling the metal to achieve desired properties. By rapidly cooling heated metal, it reduces the size of the crystal grains, which in turn makes the metal stronger. Quenching has been around for centuries, with some of the first recorded uses dating back to the middle of the Iron Age.

Steel, for instance, can be significantly strengthened to a martensite through quenching. Once heated, steel is quenched to the point where austenite becomes unstable; thus, resulting in a newer, stronger type of steel known as martensite.

Tempering

Finally, tempering is a heat treatment process

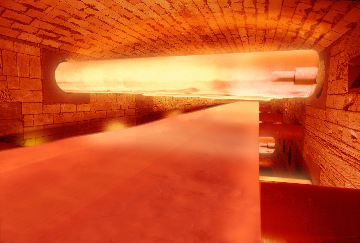

Photo credit: Thyssenkrupp