Your Cart is Empty

The art of swordmaking has been around for thousands of years, with some of the world's first swords being made of copper. In the Bronze Age (2000 to 500 BC), however, swordsmiths began making swords by casting bronze, allowing for a stronger and more durable blade. And soon thereafter, steel was introduced into the craft, allowing for even stronger swords.

But swordmaking has also evolved over the years, with swordsmiths now using a variety of modern tools and techniques. Of course, some elements of the craft remain unchanged, but there are several stark differences between the traditional craft of swordmaking and the modern craft practiced today.

Swordmaking Today

Following the decline of the Industrial Revolution, swordmaking began to decline for several reasons: first, swordsmiths could forge swords and blades out of flat steel bars. Secondly, machines become available to facilitate the process. Furthermore, guns became the standard choice of weapons over swords.

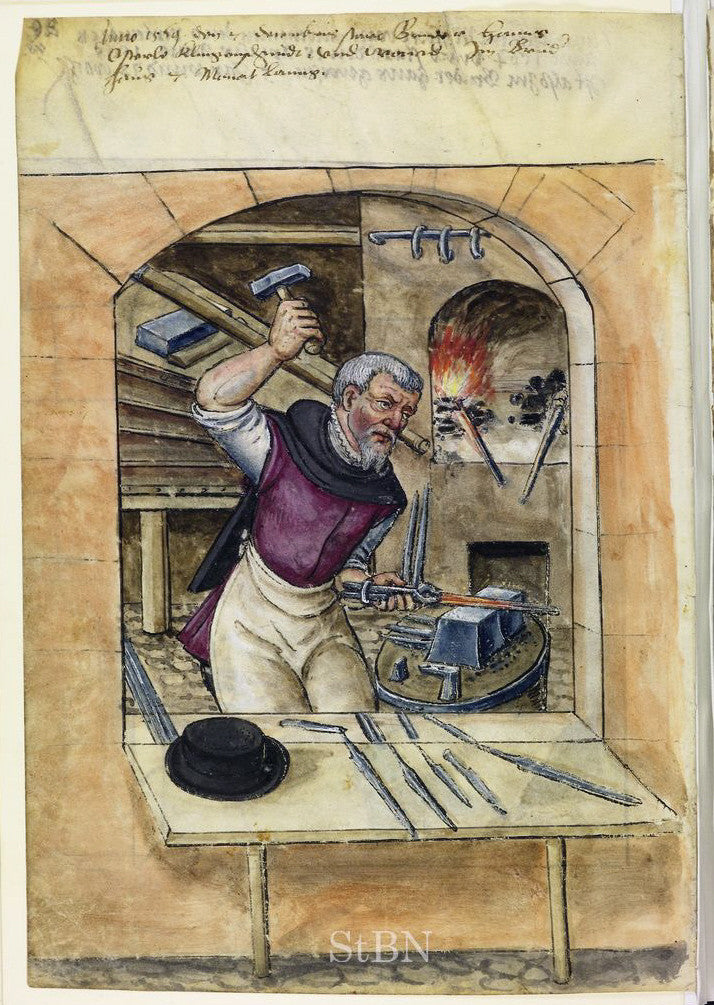

The basic principles of swordmaking, however, have remained relatively unchanged for thousands of years. Different regions have their own respective techniques, though the process typically involves smelting steel -- or multiple types of steel -- in a forge, after which the steel is repeatedly heated, hammered and folded to improve its strength and purity.

Traditional Japanese swordsmiths would perform differential heat treatment between the folding of the swords. This involves the application of clay on the blade's edge, after which both the edge and spine are quenched in water or oil. The clay acts as an insulator, allowing the blade to cool more slowly than the spine. All of these processes continue to be used in modern swordmaking -- but with a few slight changes.

Forges

In the past, forges used in swordmaking were typically fed by wood, coal or coke (a high-carbon coal). Today, these forges are most commonly fed by gas. Gas-fed forges are easier to control and provide higher maximum temperatures, which of course is essential to swordmaking. Some countries continue to use the aforementioned fuel sources, though the preferred choice of fuel for most modern swordsmiths is now gas.

Hydraulic Presses and Power Hammers

Another key difference between traditional and modern swordmaking lies in the tools used. Rather than a large "smith's hammer," swordmakers today generally use hydraulic presses and power hammers. Not surprisingly, these modern tools allow for easier and more powerful pressing of metal.

Metal Varieties

Finally, swordmiths today have access to a greater variety of metals than in the past, some of which include high-carbon steel like SAE 1075 and SAE 1095, and Special alloy steel like AISI L6.